Sustainable Aviation Fuel (SAF) removed from a tank truck for inspection.

“We could never have done it alone. We could not have done it without the recipients. We want to continue to supply them.”

Korehiro Odachi, executive officer of euglena, which develops sustainable aviation fuel (SAF) based on microalgae euglena and waste cooking oil, told Business Insider Japan in a lively voice.

I couldn’t read his expression deeply because he was wearing a mask, but I could see that his face was beaming with joy.

On September 16, euglena began introducing SAF “Susteo” manufactured by euglena to the refueling hydrant system (hereafter, hydrant facility) installed and operated by Narita International Airport (hereafter, NAA). A hydrant facility is a facility for supplying fuel to refueling spots that exist within an airport.

In other words, the introduction of fuel to this facility means that we have established a system that can supply Euglena fuel at any time according to the request of the airline company.

This is the first time that a domestically produced SAF has been introduced into a hydrant system in Japan. Considering the future of Euglena’s biofuel business, this is an extremely important step.

Advertisements

Dramatic improvement in the last mile of refueling by using airport infrastructure

Euglena, Korehiro Odachi Executive Officer, Head of Energy Company.

In 2018, Euglena constructed a biofuel demonstration plant in Tsurumi Ward, Yokohama City, and in January 2020, the manufacturing process was certified as a new standard (Annex 6) of the international standard for SAF manufacturing, the ASTM D7566 standard. rice field. Now, the bio-jet fuel produced by Euglena can be used as jet fuel.

After that, in March 2021, Euglena completed bio-jet fuel at the demonstration plant, and in June of the same year, it was introduced into a flight inspection aircraft owned by the Ministry of Land, Infrastructure, Transport and Tourism. Since then, we have introduced SAF to aircraft seven times in total.

However, Mr. Odachi

“In the past, even when we tried to fuel our planes and helicopters, we had to devise the so-called ‘last mile.’ In the last seven flights,Refueling manually using a drum can, or refueling directly by attaching a tank truck to the planewas doing”

He says that the problem was that the supply chain was not in place.

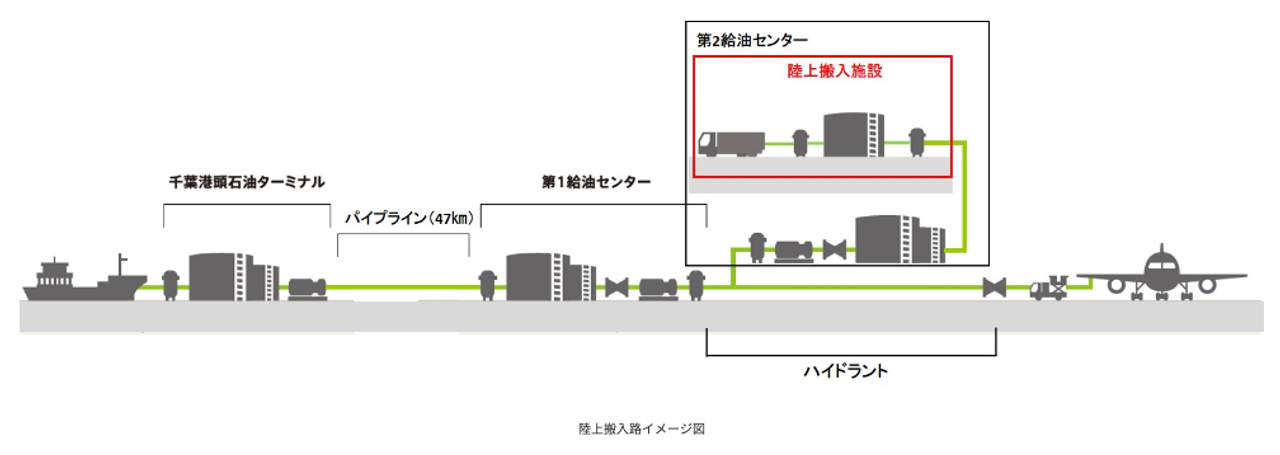

This time, it became possible to carry in to the second refueling center of NAA, using the existing fuel supply line of the airport,It will be possible to supply Susteo to 171 refueling spots (as of April 2022) in the airport linked to the second refueling center.

Euglena’s SAF will be introduced to the second refueling center by tank truck. After that, it is supplied to each refueling spot while being mixed with fuel from other companies through airport facilities. Since it meets the jet fuel standard, there is no problem even if it is mixed with fuel from other companies.

“We will be able to supply all types of aircraft, from airplanes flying from around the world to airplanes flying from Narita to the rest of the world. This is a big step forward for us,” said Mr. Odachi.

The SAF that Euglena will provide to NAA is a 1:9 mixture of bio-jet fuel and petroleum-derived jet fuel.

Bio-jet fuel is allowed to be used in a blend of up to 10% to 50% with petroleum-derived fuel, depending on its production method. Euglena bio-jet fuel can be blended up to 50% with petroleum-derived fuel.

Mr. Odachi explains why he limited the mixture to 10% this time.

“It’s possible to go straight to 50%, but I think it’s a step-by-step process. I’d like to start with 10%, then 20%, then 30%.”

talk to.

According to Euglena, fuel will be loaded onto an aircraft that actually takes off from NAA at the end of September. A spokesperson for Euglena said, “We will refrain from answering the question about fuel sales prices because they are determined by individual contracts.”

Making progress in laying the groundwork for commercial plant operations

Euglena bio-jet/diesel fuel manufacturing demonstration plant. It was built in Tsurumi Ward, Yokohama City in the fall of 2018.

Euglena is proceeding with the preliminary basic design of a biofuel (SAF, biodiesel fuel) commercial plant aiming for completion in 2025.By 2026, when full-scale operation begins, it is planned to be able to supply approximately 250,000 kiloliters of biofuel per year, equivalent to 2,000 times the current annual production volume (125 kiloliters).

However, without waiting for the completion of the commercial plant, euglena is continuing to develop sales destinations for not only SAF but also biodiesel fuel. This is probably because there is a risk that the actual introduction will be further delayed if the market is developed after the commercial plant is completed. In order to get off to a good start at the same time as the commercial plant goes into operation, it is important to create a certain social climate in which “use of biofuel” is the norm.

However, there was a problem here.

No matter how much Euglena SAF is used at the demonstration stage, the total amount of SAF that can be manufactured at present is not that large. In general, it is difficult for fuel acceptance facilities at airports to accept small amounts of fuel, and airlines have had no choice but to deal individually with using Euglena’s SAF.

Now that it has become possible to carry Euglena to airport facilities, it is now possible to use Euglena fuel in the usual scheme for airlines to purchase fuel.

Narita International Airport aims to achieve net zero CO2 emissions by 2050

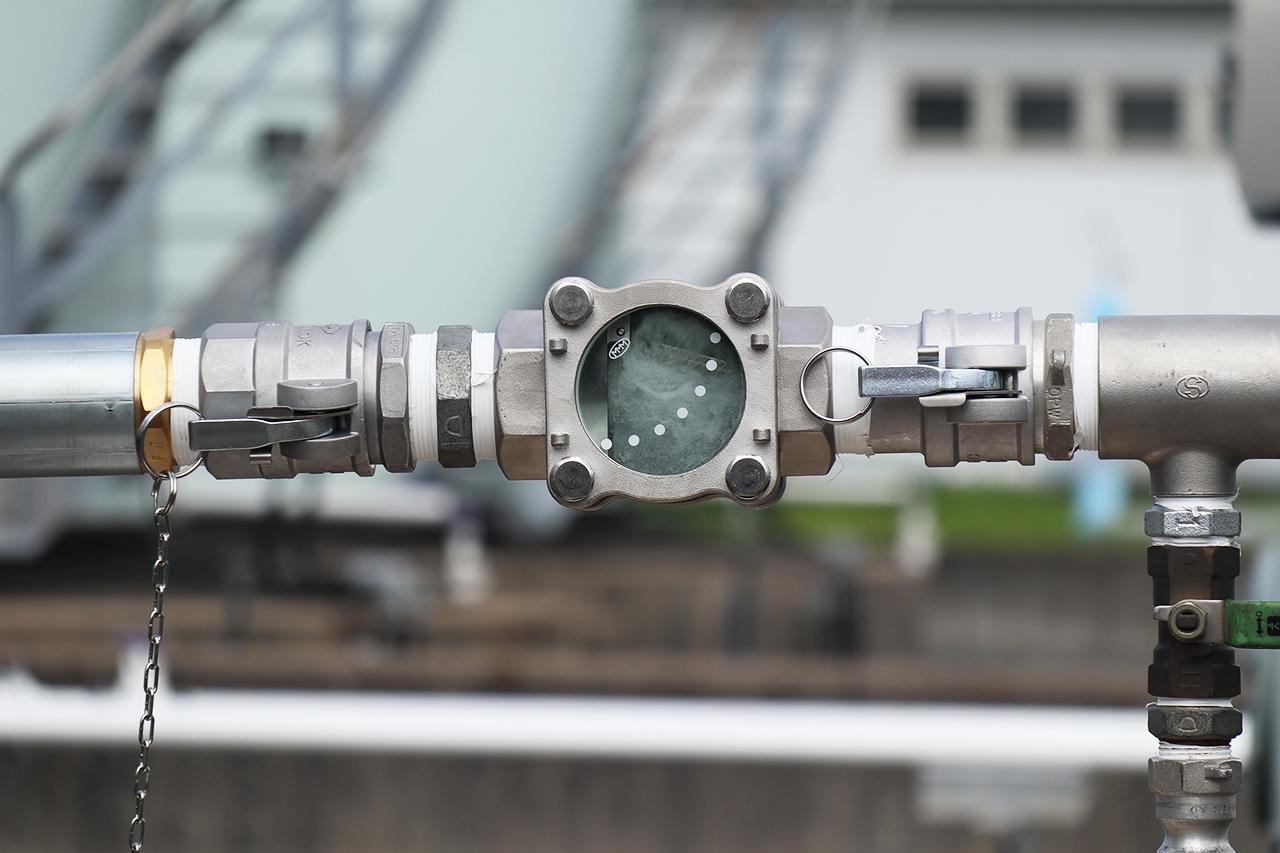

The fuel is supplied from the tank truck to the land loading facility by a hose. Narita International Airport installed this facility through renovation work.

NAA originally received jet fuel transported to Chiba Port by tanker, transported it to the refueling center through a pipeline, and stored it.Fuel was essentially delivered by “sea route.”

However, when NAA formulates “Sustainable NRT2050” in 2021, it has set a goal of reducing carbon dioxide (CO2) emissions for the entire NAA Group to virtually zero by 2050.The development of the SAF acceptance system was also one of the important indicators set as an interim goal by 2030.

In order to realize this, NAA renovated the No. 2 fueling center, which was originally used as a facility for stockpiling and maintenance. By updating the fuel management system, it is said that it has prepared a system for accepting “land routes” using tank trucks.

Toshio Tashiro, General Manager of the NAA Refueling Division, said,

“The use of SAF is the number one key point in decarbonizing aircraft. There is not a single company in Japan that manufactures SAF commercially, but we are conducting an experiment to meet international standards. There are many companies that are taking on the challenge of manufacturing in such a way.In order to actively accept SAF manufactured in such places, it would be most realistic to accept it with a tank truck.From that point of view, this facility was developed. did”

He talks about how the onshore facilities were arranged this time.

note that,In the future, not only Euglena, but when a company that produces SAF even in small quantities appears, we would like to actively accept it as an airport according to the request of the airline company.was also talking.

How much CO2 can be reduced by introducing SAF?

From the joint between the hose and the loading facility, I could see the SAF being vigorously supplied.

Then, how much CO2 emissions can be reduced by actually using the SAF produced by Euglena? In fact, at present, the exact value of the so-called LCA (Life Cycle Assessment: quantification of the environmental impact of the entire supply chain) by using Euglena’s SAF has not been disclosed.

Euglena spokesperson to Business Insider Japan

“At the moment, we are manufacturing at a demonstration plant, so it is difficult to mention the CO2 reduction rate in the LCA. We expect an 80% reduction in CO2 emissions (the reduction rate varies depending on the raw material).”

And explain the reason why LCA is not disclosed.

In the aviation sector, the International Civil Aviation Organization (ICAO) has initiated a step-by-step approach to decarbonization called the Carbon Offset and Reduction Scheme for International Aviation (CORSIA). The plan also stipulates a policy to promote the use of SAF, which has been certified as “CORSIA-eligible fuel” for its CO2 emission effects.

In July 2022, it was noted that Neste, the world’s largest SAF manufacturer in Finland, supplied CORSIA-certified SAF for the first time in the world. In order for Euglena to introduce SAF to international aircraft in the future, it will be important to obtain such certification after the commercial plant starts operation.

(Text by Takashi Mitsumura)

From the editorial department: The wording of the hydrant facility has been revised. September 21, 2022 9:15

Source: BusinessInsider

David Ortiz is an opinionated and well-versed author, known for his thought-provoking and persuasive writing on various matters. He currently works as a writer at 24 news breaker, where he shares his insight and perspective on today’s most pressing issues. David’s unique voice and writing style make his articles a must-read for those seeking a different point of view.