How did Denmark, with a population of just under 6 million, become the number one country in the world’s economic competitiveness rankings?

In the summer of 2022, Denmark is crowned number one in the global economic competitiveness rankings. In the rankings published by the Swiss business school IMD for more than 30 years, Denmark has been in the top three for the past few years, but this is the first time it has taken the top spot.

I don’t know how many Danish people around me asked me how I felt about being ranked No. 1 in competitiveness, and asked me, “Why is Denmark No. 1?” It is true that everyday scenes in Denmark seem to have nothing to do with the word “competition”. In elementary school, there is hardly any homework or tests, and there are no exams like in Japan.

“I don’t think you can ask a normal person why. It’s complicated,” said the chief of the Danish Industry Federation (DI), a business association similar to Japan’s Keidanren (Japan Business Federation), with 22 years of experience. Consultant Frank Bill.

“Most Danish companies are very small SMEs. Labor and living costs are very high, and the country is small, so the domestic market is small. andOffer products and services that overseas customers are willing to pay even at higher prices”

Mr. Frank Bill explains the characteristics of Danish companies.

Including companies that are considered big companies in Denmark, such as toy maker Lego and Novo Nordisk, known for diabetes medicine,Successful companies in Denmark have one thing in common: they are deeply specialized in one niche.It is said that And these companies are targeting the upmarket market, known as the “upmarket.”

“Of course, not all companies are like that, and there are a lot of subcontractors for big companies. It’s a well-established company,” Bill said. “And if there is a difference between Denmark and other countries, thisThe point is that even a very small company can do it, not a large company with an R&D department.” continued.

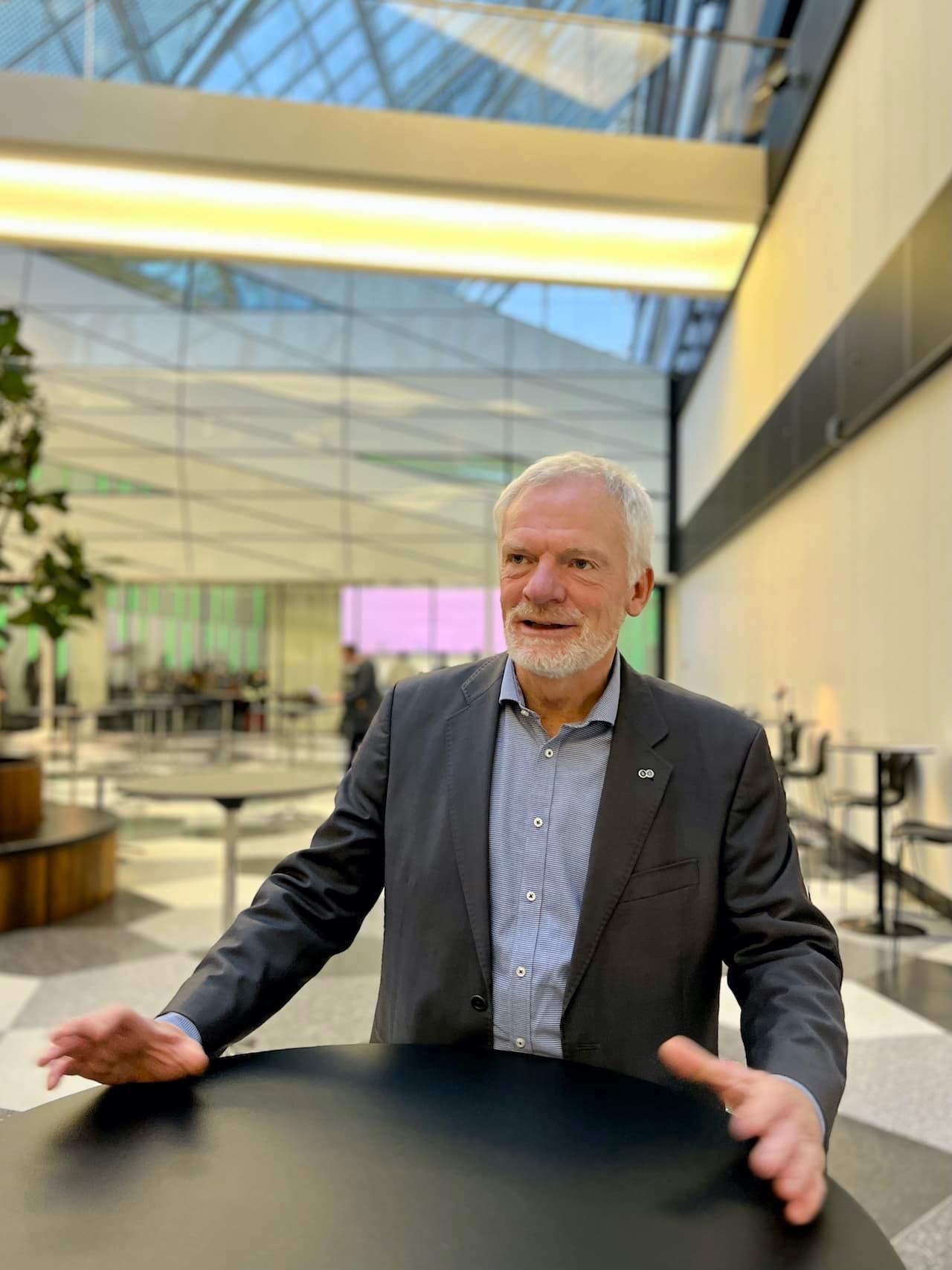

98.5% of Danish companies are small with less than 50 employees. Only 0.3% of companies have 250 or more employees.

I asked why in Denmark even a small company can achieve that. Bill then explained: It is said that the education level of general workers is high because they are focusing on education and skill improvement, such as receiving four to five years of training for occupations such as welders and machine operators. Since I was a child, I have been educated to express my opinions to my teachers, and there is a corporate culture where I complain to my superiors and the president. Growing up–.

I see. I’m sure that’s what it’s like to generalize, but this seems to make more sense if you actually visit the company and see the site directly. That’s what I thought, so I asked them to introduce me to some of those “small, successful companies that specialize deeply in their niche.”

In the second installment of the series, historian Bo Ridegaard says that Denmark has “a lot of niche industries with very specific needs and a global clientele.” rice field. He wanted to see exactly what kind of business it was.

Of the several companies Bill mentioned, I was particularly drawn to a company called FLUX, which claims to specialize in tiny parts for satellites. Few Danes know about it, but everyone in the space industry knows about it.

It is said that there is no European satellite that is flying without the parts of this company, making products that can only be made here in the world, such as “extremity of high added value”.. I have to go for this.

I ended up in a laid-back country town of about 3,000 people, far from the crisp sounds of competitiveness and innovation. The office building is also simple, or rather unspectacular.

FLUX has a company building in a laid-back country town. Is “the ultimate in high added value” really being created here?

European Space Agency Recognizes Highest Level Technical Qualification

FLUX was founded in 1980 and has 60 employees. The COO, Mr. Lars Gregason, who guided me, said that he travels overseas for two months out of the year, and often explains the products to the outside world. He explained it in an easy-to-understand manner even for an amateur like me.

Mr. Gregasson, COO in charge of satellite parts for FLUX.

“For example, I often use an iPhone charger. This is a transformer. What if I wash it away?

The same is true for satellites. Energy is received by solar panels, stored in a huge battery, and the power is divided into small portions and sent to various devices such as antennas and cameras. What we are making is the transformer inside the power supply unit (PSU), which is the heart of the satellite. It’s a very important part, without which electricity cannot be sent.”

The biggest difference from the products used on earth is the environment. With no air, no water, no UV protection from the ozone layer, it has to endure a harsh environment that can go from super hot to super cold all at once. Besides, once it takes off, it can’t be repaired for decades depending on the mission. That is why the quality of products related to space is strictly controlled by the European Space Agency (ESA).

The ESA divides manufacturers that supply satellite parts into three levels according to their technical qualifications. Among them, the highest level of “technical flow qualification” is a qualification given to the company itself, not to individual products, and it is said that all products manufactured by a company with this level meet the ESA standards.

Gregason explained that there are only six companies in the world with ESA “technical flow qualifications,” and it’s the only company that deals with magnetic components like FLUX. This is where the strength of this small company comes from.

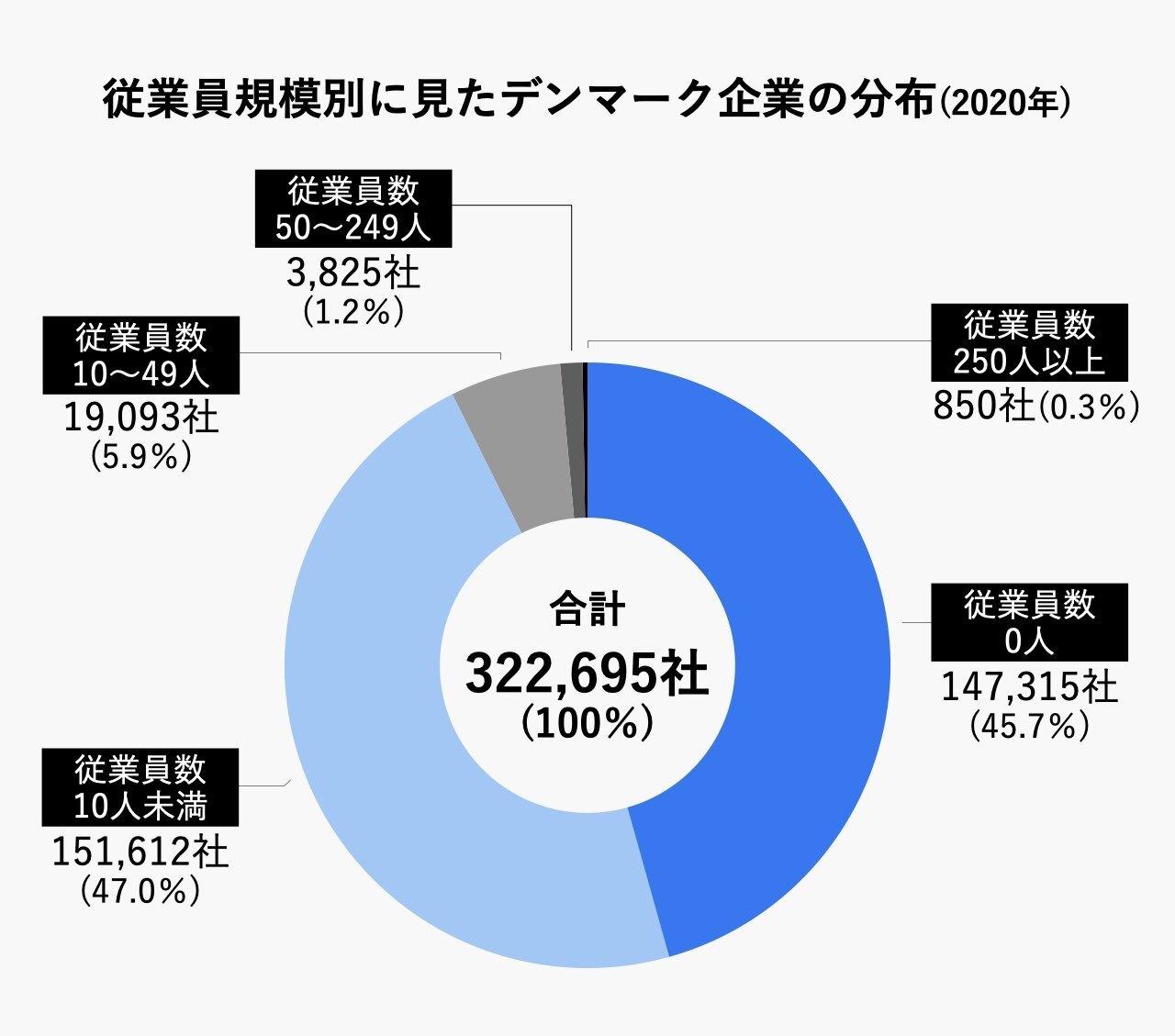

A transformer the size of a fingertip. We design the optimum combination of copper wire and magnetic material according to the customer’s request.

It was in 2020, 25 years after the company entered the space business, that it received this qualification from the ESA. The operating status of the parts used in satellites are all recorded by a computer, so if there is a problem, it is obvious where the problem was. In such a glass-enclosed environment, the company’s products have never had a problem in the past.

Business partners include global aerospace companies Airbus and Thales Alenia Space. When I asked how many satellites were flying with FLUX components, I was told, “I don’t know. Hundreds, maybe thousands.”

The company makes about 15,000 satellite parts a year, each one handcrafted and all custom designed for that one company. All requests so far have been through customer reviews,deliberately hidden from the general publicIt seems that

“Loyalty to our customers, keeping product secrets, consistent and on-time delivery of the highest quality products, have led to business expansion.”

says Gregason.

100 times the price of industrial products

FLUX has a subsidiary in Thailand where it employs 260 people, more than four times the size of Denmark. What is interesting is the division of labor between Denmark and Thailand. The division of responsibility is clearly divided according to the grade of the product,In Denmark, where labor and production costs are high, we specialize in high value-added products.Noda.

The company divides its products into three grades: “industrial,” “high-reliability (aviation),” and “space.” The difference is whether it can be repaired or replaced when broken. Products for industrial use can be repaired or replaced at any time, but when they are installed on aircraft or military aircraft that leave the ground, even if a problem occurs during flight, they must be able to withstand landing until landing. rise at once. The requirements are even higher for satellites that cannot be repaired once they leave Earth.

Of these, the subsidiary in Thailand is responsible for manufacturing industrial-grade products. Various industrial products such as transformers for electric vehicle charging facilities and transformers for wind power generators are manufactured here.

“We can produce in one week in Thailand what it takes one year in Denmark to produce. Our competitors in the Thai factory are Chinese manufacturers that mass produce. Become”

on the other hand,Products made in Denmark do not use price as a competitive advantage. It is a stance to sell the highest possible quality products at a price that matches it. As a rule of thumb, the higher the grade, the higher the price is 10 times. “Aviation” is 10 times the industrial grade, and “space” is 10 times more, so the industrial grade and the space grade are 100 times more expensive. There is a price difference.

Because the price was so high, there were times when customers negotiated, “If you can’t make it cheaper, I’ll move to a rival company.”

“I said yes. And what happened? Two years later, the customer came back. We spent two years trying to make something with the same quality as our competitors and they just couldn’t. So, And I said, ‘Of course you can, but the price has gone up in the last two years.'”

That’s a lot of confidence, I say. “If we don’t have quality, we have nothing, because we can’t compete on price,” Gregason said. During this interview, I heard the phrase “Don’t compete on price” many times.

FLUX clearly defines their competitiveness as the ability to create the highest quality products in the world, wherever possible. That’s why they buy the products of rival companies that are sold at a lower price than theirs, take them apart, and examine them.

“There’s always a compromise somewhere in quality. So we ask our customers if quality comes at a price, and if you want to go cheap, you have to compromise on quality.”

Despite being such an expensive product, the production process is said to be fully booked for the next six months. This is exactly what Mr. Bill of DI said, “a product that overseas customers are willing to pay even at a high price.”

Innovation is a “means to stay one step ahead”

Mr. Bill of DI said,One of Denmark’s strengths is its ability to innovate even in small companies., said. So where is the source of FLUX’s innovation?

Gregason told an anecdote in 2011 when Airbus approached him about a “fully electronic propulsion system for satellites.”

Satellites require some kind of thrust just to adjust their position in space or even just to keep the same position. “Chemical propulsion,” which burns fossil fuels, is a popular method, but Airbus wants to go all-electric.

“If we can do that, we will be able to replace the two to three tons of fossil fuels that we used to carry on board with hundreds of kilograms of electronic products. This will lead to a significant reduction in the cost of launching satellites, thus improving the economy. It was a very meaningful project.”

However, in order to achieve this, a new technology that had not existed before was required.

“For example, durability. Roller coasters have a load of 5G, fighter planes have a load of 11G, and if it exceeds 13G, humans die. Until then, our products had been made to withstand an average of 500G. Airbus at this time. ‘s demand was 2000G, which far surpassed the previous level.”

It started with an engineer putting out an idea on a pure white board. When creating a product using new technology, it is necessary to create a testing facility from scratch. This product was made over the course of six years, testing durability while dropping a huge piece of concrete from a high position.

Transformer for all-electric propulsion satellites developed over 6 years.

The communications satellite Eutelsat 172B, launched in 2017, was equipped with FLUX components. It is Europe’s first all-electric satellite and is described by Airbus as a “breakthrough.”

It’s a success story in retrospect, but back in 2011, Airbus said the same story was offered to all three companies. FLUX won the contract because it showed that the company would take 90% of the development costs.

“When I heard the idea of a full electronic propulsion system for satellites from Airbus, I had a gut feeling that this would be a game changer for the space business in the future. Conversely, if our company faces a crisis in the future, it will be when a competitor takes advantage of this technology, so we had to win this contract.”

The prediction that electronic propulsion systems for satellites will become the core of future business came true, and after the project with Airbus, FLUX acquired electronic propulsion system-related parts from companies in France, Spain, Argentina, Turkey, Israel, and other countries. It received an order.

While listening to this story, I remembered the competitiveness ranking of IMD. Among the 20 evaluation items, the one that Denmark gets high marks every year is the “management method” item, which shows whether it responds quickly to market changes, business opportunities, and threats. , was the top rating among 63 countries. By the way, Japan came in at the bottom of this item.

In the second installment of this series, I will explain that when trying to protect workers’ livelihoods, Japan tries to secure their livelihoods through corporate employment, but in Northern Europe they try to directly bail out workers.As a result, uncompetitive companies will be weeded out, and industrial metabolism will accelerate.I touched on the point of an expert.

The exceptional industries that the Danish government has backed up with generous subsidies are very limited, such as the renewable energy sector, and do not include the space industry. As a result, Danish space companies have always been at a disadvantage compared to companies such as France, where the government is actively supporting the space business. This is because the government-subsidized research and development costs are different.

As a Danish company, FLUX has no choice but to succeed commercially. You have to make enough money to justify the high Danish wages and high production costs.

“So for us, innovation is a way to stay one step ahead, a willingness to try new ideas.”

Simply put, a transformer is a combination of copper wire and magnetic material, but there are many types of copper and magnetic material, and the optimal combination and shape design of the product can vary in performance and weight. Become. This is where the company’s creativity and technological prowess are put to the test.

We have many types of copper wires in order to create optimal products according to the functions required by customers.

“Since all of our products are custom-designed, our employees are constantly coming up with solutions to meet the needs of our customers. You can come up with new ideas, even if you ask for them.”

Engineers involved in different projects also work in the same room, exchanging ideas while formulating design ideas.

The strength that human resources can only be nurtured here

From what I have heard so far, I understand that this company has a considerable sense of crisis in order to survive and is trying to create something that does not exist in the world. ,I’m saying that.

After all, I am in a small country in Northern Europe, Denmark, and it takes about two hours by train and car from the capital (I’m sorry to say this).

Is it difficult to secure human resources?

“It’s tough because the space business is booming right now, and public budgets are ballooning worldwide. The reason is the moon and Mars. It is very difficult to go directly to Mars from the moon.Therefore, the image of using the moon as a gas station is to load fuel there and then reach Mars.In order to keep up with this movement, countries around the world are increasing their space-related budgets. Yes – except, of course, the Danish government.”

That said, the method of securing human resources is not a method of recruiting the world’s top brains. Surprisingly,Of the 60 employees, 50 are local, and the remaining 10 are hired from Copenhagen..

I thought that this was quite different from the attitude of Copenhagen companies actively trying to recruit excellent human resources from overseas, but it is probably related to the fact that the company is located in the countryside. Besides, it seems that the ability to create world-class products with such a local orientation shows the high level of ability of ordinary Danes.

I wrote that this company has ESA’s “technical flow qualification”, but this means that all departments such as material purchasing, engineering department, sales department, etc. meet ESA standards. is an ESA-accredited educational institution.

Conversely,People who make FLUX level parts can only be trained at this company,I’m saying that. This is one of the company’s strengths, as long as they have a certain level of knowledge, they can be trained in the company.

An operator who has received ESA qualification through in-house training will implement the design drawn by the engineer.

In an interview with Bo Ridegaard, a historian who appeared in the second installment of this series, when I asked him why Danish companies are so competitive, one of the things Mr. Ridegaard said was, It was to drop it.”

Considering the example of FLUX, I think that’s certainly true. We explore new ideas on a daily basis, sometimes challenging big innovations that have never existed before. By giving shape to this new technology, we will grow our human resources and seek opportunities to take on the next “game changer” project.

This small company has managed to do just that, and has survived more than 40 years with little government backing. “It’s too niche to fail,” said Mr. Ridegaard, but this company also seemed to see a part of Denmark’s economic competitiveness.

Yoko Inoue: Journalist and communication advisor living in Denmark in Northern Europe. Graduated from the University of Tsukuba International Relations and completed the Kennedy School of Government at Harvard University. After working for the Yomiuri Shimbun in charge of the Ministry of Land, Infrastructure, Transport and Tourism and the Ministry of the Environment, he became a correspondent for the Washington bureau. In 2015, she moved to the capital Copenhagen when she became pregnant, and now she lives with her Danish husband, eldest daughter, and eldest son. In addition to writing for the media, she also appears on TV, speaks at events and supports Danish companies. Her Twitter is @yokoinoue2019. She also posted a note (@yokodk).

(Serialized logo design by Mio Hoshino, editing by Ayuko Tokiwa)

Source: BusinessInsider

Emma Warren is a well-known author and market analyst who writes for 24 news breaker. She is an expert in her field and her articles provide readers with insightful and informative analysis on the latest market trends and developments. With a keen understanding of the economy and a talent for explaining complex issues in an easy-to-understand manner, Emma’s writing is a must-read for anyone interested in staying up-to-date on the latest market news.